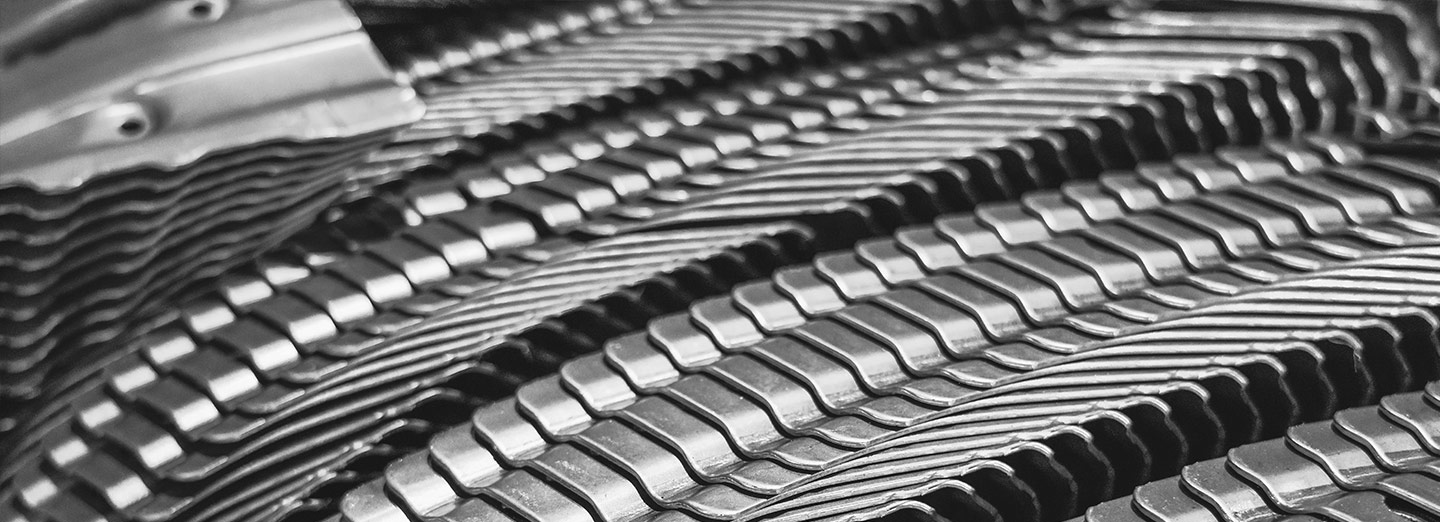

Csepel Autó Kft. has been involved in the production of parts requiring press technology since 1950. From that date until the 1970s, it mainly produced the full-scale production of sheet metal parts for Csepel trucks, then from the 1970s onwards, it supplied pressed parts for IKARUS buses with a partially modified profile, and then MAN engines. For a short time, VOLVO trucks were produced at Csepel Autó, then many transformations and changes took place in the life of the long-established company, until the turn of the millennium.

The next significant and decisive turning point in the company’s history occurred in 2004, when it came under the ownership of our company group. Its field of activity has not changed, Csepel Autó Kft.’s profile still includes high-quality sheet metal processing, pressing and stamping activities. After a short time, a leap in logistics and quality followed in 2008, when our new, 3,000m² production hall was completed in the area of the ÁTI-Sziget Industrial Park. As a result, all the company’s activities – Draspó Tempó Kft., Csepel Autó Kft. and Autóker Gamma Kft. – are concentrated in one place, including the application of press technology. Compared to before, we continue production under more modern conditions, with an increased number of high-performance machines and with a larger capacity.